Details

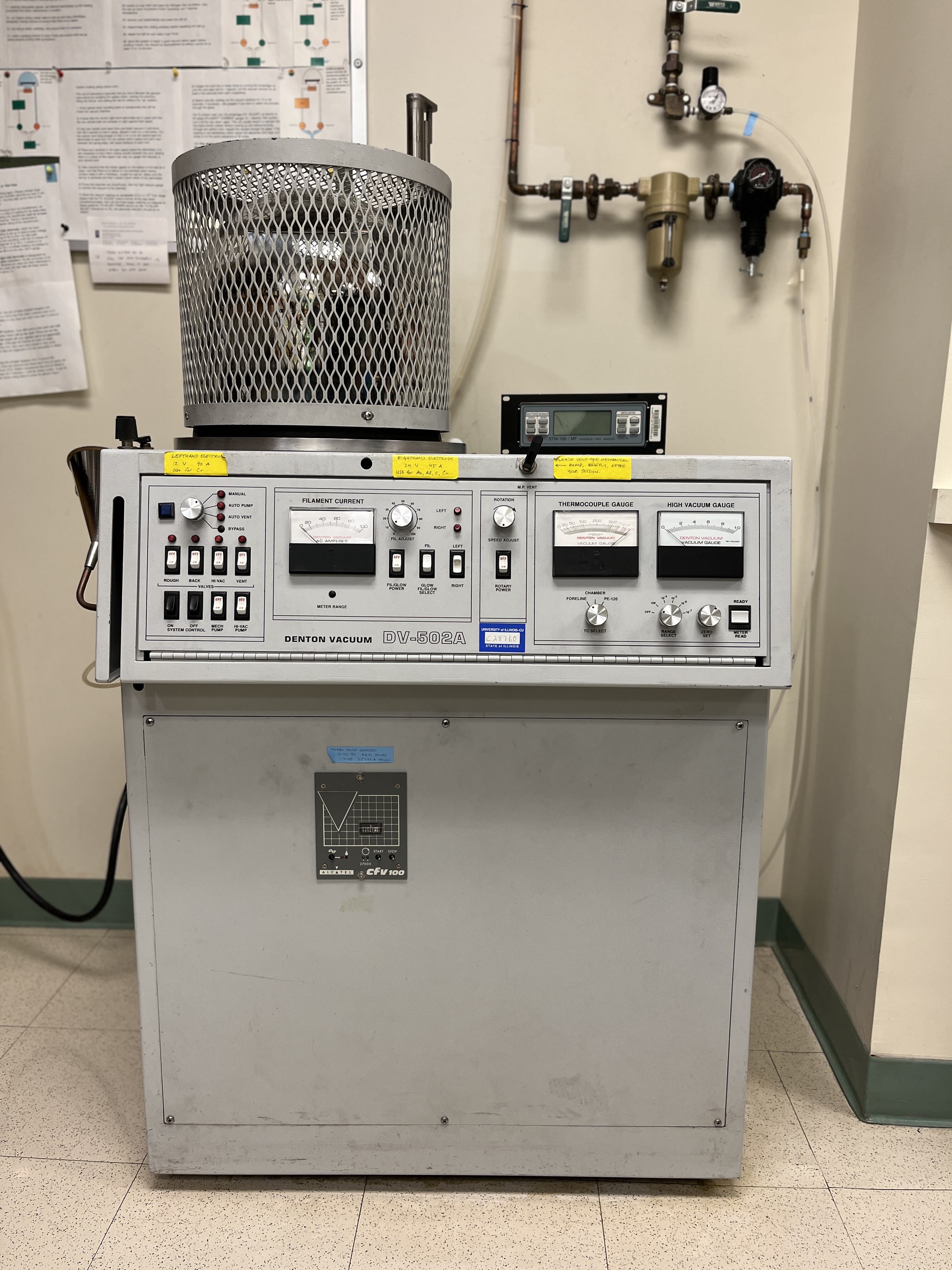

Dual Source Metal Evaporator

This Denton DV-502A automatic turbo-pumped carbon evaporator has been reconfigured to permit successive coatings of two different metals without breaking vacuum. The most common example of dual-metal coating is the application of 10 to 12 Angstroms of chromium onto super clean and dry glass slides or coverslips, followed immediately by an application of (often) 50 nanometers of gold. The chromium serves as a transition or adhesion layer that allows the gold to adhere permanently to the glass. The transformer that powers the electrodes has been wired with two separate circuits so that the left-side electrode (Cr) operates at 12 volts/90 amps and the right-side electrode (Au, Pt, Ni, Al, C, and Ag, among others) operates at 24 volts/45 amps. Metal coating may of course be performed with or without chromium, as desired. The system utilizes a film-thickness monitor to ensure accurate coating thickness, a shutter system for switching sources, and a set of masks or slide carriers to facilitate coating.

Features

- 250 LPS turbo pump

- integral LN2 trap

- manual control of evaporation using baskets, thread, or electrodes

- rotary stage may be installed

For additional information about this piece of equipment, see the Calendars, Contacts, and Fees pages.

| Primary Contacts | |

|---|---|

| Secondary Contacts |

|

| Manufacturer | Denton Vacuum, Inc. |

| Equipment Model | DV-502A |

| Location | Wet Lab |

| Phone Numbers | (217) 265-5071 |

Imaging Technology Group

405 North Mathews Avenue, Urbana, IL 61801 USA

(217) 300-0566